Alle producten

-

Aluminium striprol

-

Kleur Met een laag bedekte Aluminiumrol

-

Aluminiumfoliebroodje

-

Aluminium plaatplaat

-

De Schijf van de aluminiumcirkel

-

polyesterfolie gelamineerd met aluminiumfolie

-

Aluminium Geruite Plaat

-

Aluminium Diamond Plate Sheet

-

In reliëf gemaakt Aluminiumblad

-

Geanodiseerde aluminiumplaat

-

Het Blad van het spiegelaluminium

-

Bakje van aluminiumfolie

-

De Doos van de aluminiumfolielunch

-

Gebruikbare BBQ-grill

-

MartinDe eerste keer werkten wij met Yongsheng-Aluminium samen, vonden wij het zeer gemakkelijk, omdat de levertijd van de goederen zeer snel was, en de bedrijfsleider was ook zeer professioneel. Hij hielp me sommige technische problemen oplossen. De goederen werden ontvangen op 2021.1.20 en de kwaliteit van de zeer goede goederen!

MartinDe eerste keer werkten wij met Yongsheng-Aluminium samen, vonden wij het zeer gemakkelijk, omdat de levertijd van de goederen zeer snel was, en de bedrijfsleider was ook zeer professioneel. Hij hielp me sommige technische problemen oplossen. De goederen werden ontvangen op 2021.1.20 en de kwaliteit van de zeer goede goederen! -

Alice SuOns bedrijf en Yongsheng-Aluminium hebben bijna drie jaar samengewerkt. Wij hebben de fabriek bezocht, is Yongsheng een professionele aluminium materiële leverancier, hebben wij aluminiumstroken in hun fabriek, gekocht en samenwerking op lange termijn gehandhaafd.

Alice SuOns bedrijf en Yongsheng-Aluminium hebben bijna drie jaar samengewerkt. Wij hebben de fabriek bezocht, is Yongsheng een professionele aluminium materiële leverancier, hebben wij aluminiumstroken in hun fabriek, gekocht en samenwerking op lange termijn gehandhaafd. -

ZoeyWij kopen aluminiumcirkel van Yongsheng-Aluminium en verschepen hen aan Ghana. Wij hebben zulk een behulpzame verhouding twee jaar gehandhaafd, en wij moeten elke maand verschepen. Tijdens samenwerking, is elke verbinding zeer efficiënt, en de accountbeheerder zal ons helpen problemen snel oplossen. Wij zijn zeer gelukkig om een betrouwbare leverancier te vinden.

ZoeyWij kopen aluminiumcirkel van Yongsheng-Aluminium en verschepen hen aan Ghana. Wij hebben zulk een behulpzame verhouding twee jaar gehandhaafd, en wij moeten elke maand verschepen. Tijdens samenwerking, is elke verbinding zeer efficiënt, en de accountbeheerder zal ons helpen problemen snel oplossen. Wij zijn zeer gelukkig om een betrouwbare leverancier te vinden. -

Amin MazlumWij hebben een totaal van bijna 500 ton in reliëf gemaakte rollen van het kleurenaluminium van Yongsheng-Aluminium gekocht. De kwaliteit is stabiel geweest en de levertijd is snel. Mijn klanten zijn zeer tevreden met mijn producten. Wij zullen met Yongsheng-Aluminium blijven samenwerken.

Amin MazlumWij hebben een totaal van bijna 500 ton in reliëf gemaakte rollen van het kleurenaluminium van Yongsheng-Aluminium gekocht. De kwaliteit is stabiel geweest en de levertijd is snel. Mijn klanten zijn zeer tevreden met mijn producten. Wij zullen met Yongsheng-Aluminium blijven samenwerken.

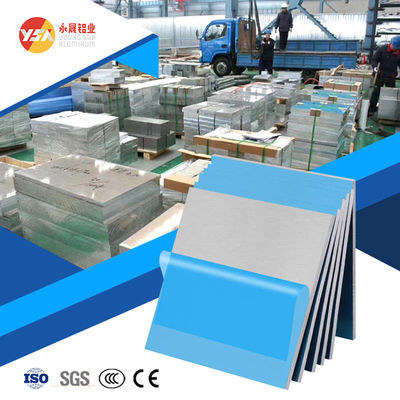

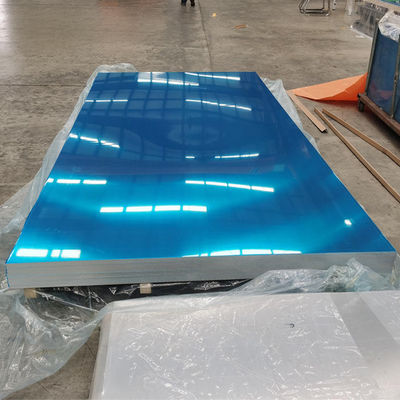

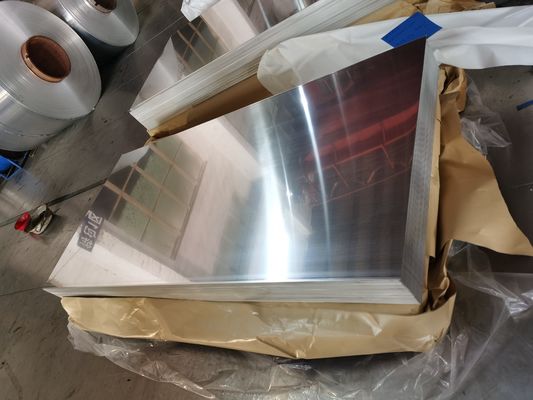

1100 1060 Aluminum Sheet 0.5mm Thickness for Food Packaging/Electronic Heat Dissipation

| Plaats van herkomst | Provincie Henan, China |

|---|---|

| Merknaam | YONGSHENG |

| Certificering | ISO, RoHS |

| Modelnummer | 1000 3000 5000 -serie |

| Min. bestelaantal | 2 ton |

| Prijs | 3050-3250 USD/Ton |

| Verpakking Details | Standaard zeewaardige verpakking |

| Levertijd | 7-25 dagen na bestelbevestiging |

| Betalingscondities | L/c, d/a, d/p, t/t |

| Levering vermogen | 5000 ton per maand |

Contacteer me voor vrije steekproeven en coupons.

whatsapp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Als u om het even welke zorg hebt, verstrekken wij de online-Help van 24 uur.

xProductdetails

| Trefwoord | Aluminium blad | Materiaal | Aluminium legeringsmetaal |

|---|---|---|---|

| Woedeaanval | O-H112 | Breedte | 10-2000 mm |

| Dikte | 0,15-200 mm aangepast | Vorm | Vlakke plaat |

| Oppervlaktebehandeling | Molenafwerking | Verwerkingsservice | Buigen, afstemmen, lassen, ponsen, snijden |

| Haven | Qingdao, Shanghai, Tianjin | Steekproef | Vrij |

| Markeren | 0.5mm aluminum sheet for food packaging,1060 aluminum plate for heat dissipation,1100 aluminum sheet with 0.5mm thickness |

||

Productomschrijving

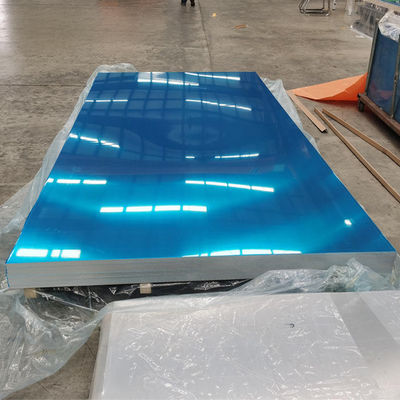

1100 1060 Aluminiumplaat 0,5 mm Dikte

Premium aluminiumplaat, speciaal ontworpen voor voedselverpakkingen en elektronische warmteafvoertoepassingen, met een dikte van 0,5 mm voor optimale prestaties.

Overzicht van de serie van aluminiumlegeringen

| Alloy serie | Kernkenmerken | Typische toepassingen |

|---|---|---|

| 1000-serie | Puur aluminiumplaat - zachte textuur, zeer corrosiebestendig, uitstekende elektrische/thermische geleidbaarheid, lage sterkte, gemakkelijk te verwerken |

|

| De serie 2000 | Al-Cu legeringsplaat - hoge sterkte, bestand tegen hoge temperaturen, vereist oppervlaktebehandeling voor corrosiebescherming |

|

| 3000-serie | Al-Mn legeringsplaat - middelmatige sterkte, uitstekende corrosiebestendigheid, goede plasticiteit, gemakkelijk te lassen |

|

| 4000-serie | Al-Si legeringsplaat - laag smeltpunt, slijtagebestendige, voornamelijk gebruikt in gietmaterialen |

|

| 5000-serie | Al-Mg legeringsplaat - hoge sterkte, uiterst sterke corrosiebestendigheid, uitstekende lage temperatuurprestaties, gemakkelijk te vormen |

|

| 6000-serie | Al-Mg-Si legeringsplaat - warmtebehandelbare versterking, middelmatige sterkte, uitstekende corrosiebestendigheid, superieure bewerkbaarheid |

|

| 7000-serie | Zeer hoge sterkte, corrosiebescherming, hoge prijzen |

|

Technische en procesvoordelen

Volwassen smelt- en giettechnologieën:Onze fabriek handhaaft nauwkeurige temperatuurcontrole voor verschillende aluminium plaat materialen waaronder 1 serie (zuiver aluminium), 3 serie (aluminium-manganesolie) en 5 serie (aluminium-magnesium-legering).De smelttemperatuur van puur aluminium wordt nauwkeurig gecontroleerd binnen 660-700°C. Geavanceerde ontgas- en slakkenverwijderingsprocessen minimaliseren interne defecten,met mechanische eigenschappen die fluctueren binnen ± 5% - aanzienlijk beter dan het gemiddelde van de industrie van ± 8%.

High-precision rollen en oppervlaktebehandeling:Uitgerust met geavanceerde vier rollen omkeerbare koudwalmachines die aluminiumplaten van 0,1 mm tot 10 mm dik kunnen verwerken.voldoen aan strenge eisen voor elektronische en verpakkingstoepassingenEen volledig scala aan oppervlaktebehandelingen, waaronder anodisatie, elektro-etchingcoating en filmcoating, beschikbaar met aangepaste afwerkingen (spiegel, mat of geborsteld).De coatings slagen voor de zoutspray-test (neutrale zoutspray-test ≥ 500 uur).

Rapide reactie op het proces:Our established "process parameter database" enables quick matching of exclusive production processes for specialized applications including marine-grade 5 series aluminum plates and automotive 3 series lightweight aluminum platesDe bevestigingscyclus van het bestelproces is 30% korter dan het gemiddelde in de industrie.

Kwaliteitscontrole

Rigoureuze selectie van grondstoffen:Wij gebruiken uitsluitend aluminiumblokken van hoge zuiverheid die voldoen aan de GB/T3190 (China) of ASTMB209 (VS) normen met een aluminiumgehalte van ≥ 99,7%.Elke partij wordt onderworpen aan spectrometercompositietests om prestatieproblemen door onzuiverheden te voorkomen.

Productiebewaking in realtime:Belangrijke processen (smelting, rollen, gloeien) zijn voorzien van online detectieapparatuur met realtime samenstelling en temperatuurmonitoring.Laserdiktemeters regelen de rollingprecisie terwijl thermoparen de temperatuur van de oven uniform houdenProductiegegevens worden om de 10 minuten geregistreerd voor volledige traceerbaarheid.

Uitgebreide inspectie van het eindproduct:Vier niveaus inspectie protocol dat uiterlijk, afmetingen, prestaties en weerbestandheid bestrijkt.micrometers en vernier-klemmen voor dimensiecontroles (monsterafname ≥ 5%);, universele materiaalonderzoek op mechanische eigenschappen en hoog/laag temperatuurcyclusonderzoek (-40°C tot 80°C, 50 cycli) voor buitentoepassingen.Niet-conforme producten krijgen 100% verwerking met een fabrieksafslag die consequent hoger is dan 99.8%.

Productgegevens

Producttoepassingen

Geadviseerde Producten